If your are experiencing wheel balancer problems then some of these points will enable you to identify the issue. Obviously if you have one of our wheel balancers and are experiencing problems then please call our technical team. Digital display is flashing on start up? Off set distance ruler is not in place properly. Return […]

Frequently Asked Questions

Do you have some unaswered questions? Do you want to know the correct way to repair a tyre, or how to use adhesive weights? What’s the latest TPMS information?

At Tyre Bay Direct we always like to keep our customers up to date with the latest information from the Tyre Industry as well as some articles to give those starting out a good grounding in the process of Tyre Fitting.

Our Knowledge base continually grows with more and more information available so please feel free to contact us if the information you require isn’t here, you too can add to our knowledge base.

If you have a tyre changer issue then this quick guide may help you identify the problem. If you encounter a snag, there is sometimes a textbook solution. Read our tyre changer troubleshooting guide to find out more. If you have one of our Tyre Changers and you have an issue, don’t hesitate to give […]

Wheel alignment, sometimes referred to as breaking or tracking, is part of standard automobile maintenance that consists of adjusting the angles of wheels so that they are parallel to each other and perpendicular to the ground. The meaning of wheel alignment can often be confused, as the term is misleading. Rather than referring to your […]

Picking Your Tyre Fitting Equipment With so many different tyre machine combinations it can be a little confusing when setting up a tyre fitting business. Here at Tyre Bay Direct we want to make choosing the best tyre equipment for your needs as simple as possible. With over 50 years of experience in the tyre […]

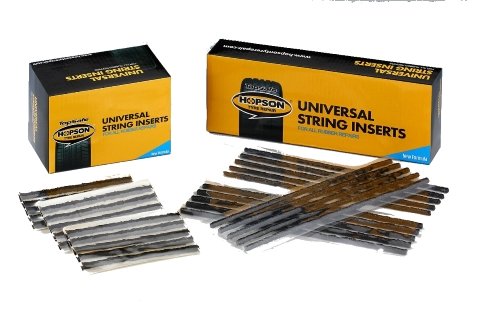

Puncture repair using patch and plug combination repair materials We have a wide range of tyre repair materials such as patch and plug combos, universal patches, tube patches, radial patches and cross ply patches. These are used on motorcycle tyres, passenger car tyres, LGVs tyre and even truck and agricultural tyres. The most common […]

- 1

- 2